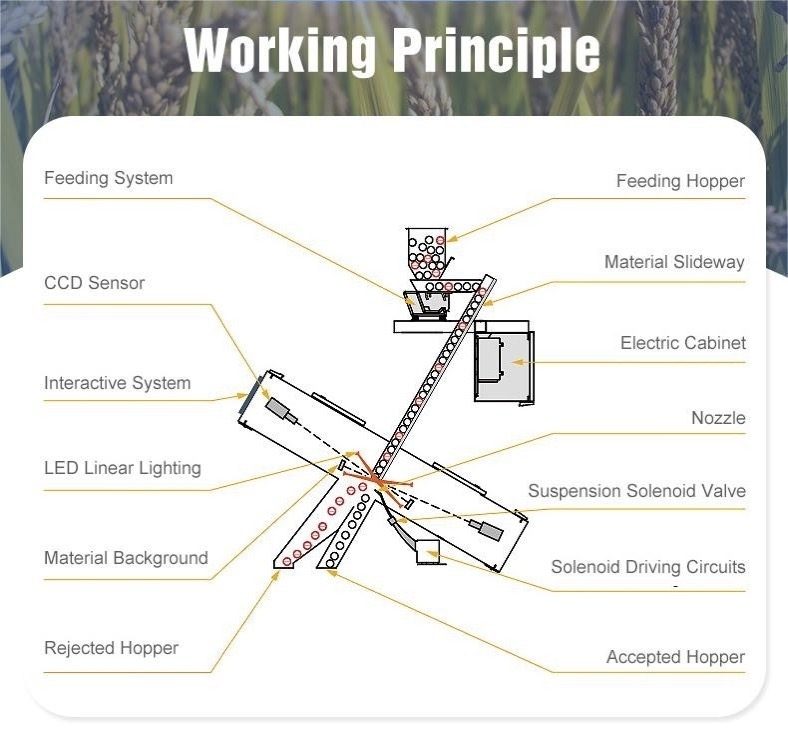

The chute color sorter is composed of a hopper, a chute, a photoelectric sensor and an air blowing device. The material flows evenly into the chute from the hopper, and the photoelectric sensor detects the material, and when the color of the material is inconsistent with the set color threshold, the photoelectric sensor will send a signal to blow the material out of the chute.

The chute type color sorter directly detects the material through a photoelectric sensor, while the belt type color sorter blows the material out of the belt through a fan and then detects it.

Chute sorters are suitable for materials of various shapes, sizes, densities and fluidity, including fruits, vegetables, nuts, grains, ores, etc. The belt type optical sorter is suitable for materials with uniform shape, size and density, and is not suitable for materials with poor fluidity.

The advantages of the chute color sorter are a wide range of applications, high sorting accuracy and simple operation. The disadvantage is that the equipment is large in size and occupies a large area. The advantages of belt type optical sorter are small size, small footprint and high sorting accuracy. The disadvantage is that the scope of application is narrow, and it is not suitable for materials with poor fluidity.